-

Our Mission

Our basic philosophy is to design, produce and market competitive products worldwide, in line with customer expectations and strategic goals, by following a superior understanding of business ethics and a transparent, accountable and responsible management approach based on sustainable quality.

-

Our Vision

We aim to be a global leader in our sector, following the principles of equality, transparency, accountability and responsibility that form the basis of corporate governance, growing rapidly with its strong brands and offering solutions based on innovation, developing its own technology and integrating continuity in the satisfaction of its social stakeholders with the philosophy of excellence in its products.

Our Services

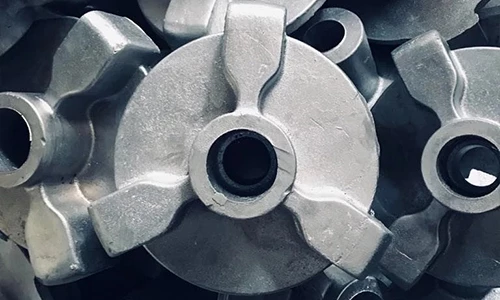

CASTING

1 electric cooker with 350kg capacity

1 gas stove with 250kg capacity

One-piece casting capacity from 0.10 kg to 600 kg. Green sand, resinous sand and permanent molds can be cast and it has an annual casting capacity of 150 tons.

DEGASING AND ANALYSIS

With our latest system degassing machine, nitrogen gas is given to the molten metal, and hydrogen spaces that may occur in the part are destroyed and a perfect surface quality is created after processing.

A sample is taken from the molten aluminum to be poured, and material metal analysis is performed with a spectrometer analysis device. It allows our products to be cast in the alloy requested by our customers.

SANDBLASTING

Sandblasting process; It is applied on the part by spraying suitable abrasives at high pressure with the help of air pressure.

It cleans the surface of the produced part and makes the surface appearance perfect.